PDU Buying Guide: the Best PDU for Your Power Design

The requirements for power in data centers are steadily on the increase, which has triggered the constant revolutions of the relevant equipment, like power distribution units (PDUs). PDUs are available with a variety of different features, power ratings, and input and output cord combinations. This guide has provided several practical consideration factors for PDU selections in power designs, which may help you to make a wise decision for your data center.

Five Steps to Select the Right Rack PDU

Step 1. Estimate Your Power Capacity

Once the power requirements are established, the rack PDUs will be required to provide at least enough power to support the rack's load. Therefore, determining the power consumption of the equipment to be protected is in the first place. The calculation procedure is straightforward: Firstly, add up the actual or anticipated power consumption of the equipment to be protected. Then spare extra headroom to accommodate possible future changes like derating and growth. Finally, add extra capacity to support redundancy configurations. Three major methods can be used to estimate the maximum power required:

Method 1: Refer to the provided nameplate

The label attached to the device indicates how much energy it uses. When the given information is described in amps instead of watts, just multiply amps by voltages to get a watts figure. Note that the expected numerical value offered by the supplier is normally the theoretical maximum amount. The actual power consumption may be lower in day-to-day operations. However, it's better to do your calculations based on theoretical maximum power draw even if the devices don't continually operate at a maximum level.

Method 2: Turn to the online power calculator

Several mainstream manufacturers including Cisco, Dell, and HP have offered online calculators that can more precisely estimate the actual power draw accounting for the specific configurations (number and type of cards, drives, etc.).

Method 3: Figure out the actual power consumption

For instance, the aid of the tool—a watt-hour meter, to measure the amount of electricity that passes through the equipment at a given moment or over a period of time. Besides, intelligent PDUs are able to monitor power usage for each outlet in real time and collect accurate power usage statistics. Detailed power information is provided to the level of individual receptacles.

After calculating the total power consumption, you may rest assured to choose the PDUs that meet your demands in view of the power ratings. The rack PDUs in a broad range of power ratings can be roughly classified into three categories:

-

Standard density PDUs (up to 5kW)—ideal for wiring closets and equipment rooms that house traditional devices.

-

High-density PDUs (5kW to 10kW)—offer combinations of receptacle types to support more power-hungry racks.

-

Ultra-high-density PDUs (10kW and up)—afford up to 48 receptacles for racks with multiple-blade chassis and servers, optimal for server consolidation.

Step 2. Choose the Available Input Power to the Facility

The input power can be further divided into two main parts: single-phase and three-phase. The former uses one phase of AC power, while the latter adopts three single-phase waves together, each wave reaching its peak at offset times.

At the rack level in a typical data center, the power distribution unit is either single-phase or three-phase:

-

Single-phase: Designed for lower-density applications. The single-phase PDUs are suitable for traditional 1U/2U servers. Many residences and small business locations are suggested to adopt PDUs with single-phase power.

-

Three-phase: Intended for higher-density racks. The three-phase PDUs will offer optimal choices for transferring power over long distances for higher-wattage applications and sometimes are applied in the utility grid, in facilities that power heavy-duty motors and other large loads.

Sticking to single-phase PDUs seems to be cost-effective for the investment in initial stages, however, three-phase PDUs will reduce the number of cables that need to be brought in and managed in copper cablings. If switching from single-phase 208V to three-phase 208V distribution, only one extra wire is required in each power drop. Got 73% more power for only 25 to 33% of copper cables. For those requiring a large number of cables, adopting three-phase PDUs may save both money and space.

The table below shows the continuous power capacity in kW at each amperage. The bold values represent the common power levels that are generally recommended by engineers.

| Single-Phase | Three-Phase | ||||

|---|---|---|---|---|---|

| 120V | 208V | 240V | 208V | 415V | |

| 20A | 1.9kW | 3.3kW | 3.8kW | 5.8kW | 11.5kW |

| 30A | 2.9kW | 5.0kW | 5.8kW | 8.6kW | 17.3kW |

| 40A | 3.8kW | 6.7kW | 7.7kW | 11.5kW | 23.0kW |

| 50A | 4.8kW | 8.3kW | 9.6kW | 14.4kW | 28.8kW |

| 60A | 5.8kW | 10.0kW | 11.5kW | 17.3kW | 34.5kW |

Step 3. Check the Supported Power Connections

The U.S. National Electrical Manufacturers Association (NEMA) and the International Electrotechnical Commission (IEC) are the two mainstream standards that most PDU plugs and outlets accord with.

Input/Output Power: Which Type of PDU Plug/Receptacle Do You Need?

You're more likely to have locking NEMA connectors like NEMA L5, NEMA L6, and NEMA L15 in data centers. IEC series of IEC 60309 and IEC 60320 provide other options, among which C13 and C19 are the commonly-used types. NEMA input connectors are made in current ratings from 15A to 60A, while IEC standards allow up to 250A, but with typical 16A to 63A for serving IT equipment.

The selection of PDU receptacles for rack device plugs is also crucial. For the power supplies in smaller rack-mount equipment such as 1U/2U servers, typically use the C13/C14 connection, while the power supplies in the larger blade and modular switch equipment normally use the higher amperage C19/C20 connection. Both C13 and C19 outlets that provide locking features to prevent accidental disconnection of IT equipment are typically used in rack IT deployments.

How Many PDU Receptacles Do You Need?

When it comes to the counts of the PDUs, C19 outlets with higher counts will be beneficial, because these outlets support both devices with a C14 or C20 connector. A C13 outlet cannot be used to power a higher amperage C20 connector. For a practical situation, suppose a rack houses 10 traditional servers, each with dual power supplies. A PDU with at least twenty C13 sockets for those 20 power cords is needed then. If you intend to fill your rack with 1U servers, you will need a PDU that can accommodate 42 power cords.

Step 4. Confirm the Installation Plan

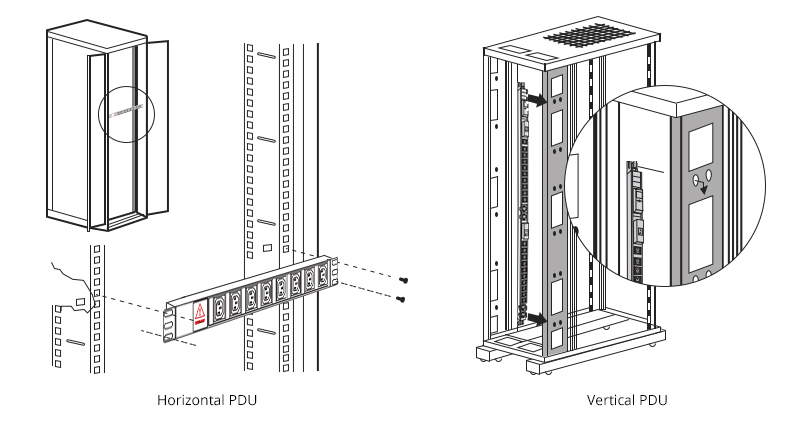

A rack PDU can be mounted horizontally or vertically depending on your installation plan. Installing horizontally inside the rack is one option, which may take up RU space; another choice is to mount a PDU vertically on the back or side of the enclosure without taking up any RU space. It's common to see vertically mounted PDUs on the left or right side of a data center cabinet.

Step 5. Ensure Your Required Functionalities of PDUs

If you only need basic power distribution without local or remote power metering requirements, picking basic PDUs will economize the expense at affordable costs. If you want to know how much power is flowing through the PDU, you can select a metered PDU featuring local power monitoring that continuously measures and records the current flowing through the PDU on each phase. If you require the function of remote monitoring or management, monitored PDU and switched PDU will meet your demand respectively. For an advanced function like power redundancy, ATS PDUs will suit you best.

The chart below will give a clear illustration that may help you identify these common PDU types.

| Basic | Metered | Monitored | Switched | ATS | |

|---|---|---|---|---|---|

| Reliable in-rack power distribution; Multiple outlets; Secure mounting |

✔ | ✔ | ✔ | ✔ | ✔ |

| Digital load meter reports power consumption in amps | ✔ | ✔ | ✔ | ✔ | |

| Network interface; Enables remote monitoring and control |

✔ | ✔ | ● | ||

| Switched outlets programmable or real-time power control | ✔ | ● | |||

| Individually switched outlets; Individual programmable or real-time outlet control |

● | ||||

| Auto-transfer switching; Redundant power for non-redundant equipment |

✔ |

Annotations:

✔ indicates all models in this product family possess the feature.

● means some of the models in this product family have the feature.

PDU Recommendations for Common Applications

Aside from the theoretical factors, whether this type of PDU suits your deployments mainly depends on the practical applications. Find the application scenario of your current situation, and you may take what we've recommended into consideration.

| Application | Demand for PDU |

|---|---|

| Small or Medium Business | Portfolio of 120V and lower power ratings. Economical basic or metered input models. |

| Remote or Branch Offices | Portfolio of 120V and lower power ratings. Control unused outlets to prevent unauthorized use. Without requiring local IT staff assistance. |

| Enterprises or Data Centers | Up to 208V three-phase 22kW for high-density applications. Configure up to 54 outlets or less for smaller racks. Simplify load balancing with alternating phase outlets. Save time by rebooting devices from the operations center. Measure for Level 3 power usage effectiveness (PUE). |

Summary

Selecting a rack PDU after understanding the type of equipment that will be installed. IT gear will dictate outlet type and quantity, as well as power consumption requirements. Additional consideration should be taken for actual application scenarios in order to make better decisions. Find the right type of PDU with proper specifications and functions to optimize the current power architecture and create a more manageable data center.

Related Articles:

Explore the Evolution and Importance of Power Cords in Modern Technology

You might be interested in

Email Address

-

PoE vs PoE+ vs PoE++ Switch: How to Choose?

May 30, 2024