- English

- German

- French

- Spanish

- Japanese

- Italian

- Chinese

- Chinese (traditional)

- Home

- Blog

- Case Study

- Knowledge Center

- Encyclopedia

- Story

- Video

- Blog Type

- Product

- Topic

- Region

Hot Search

- Product Updates

- Share FS

- PoE Switch

- Networking

- Networking Devices

- Home

- Blog

- Case Study

- Knowledge Center

- Encyclopedia

- Story

- Video

-

- Home

- Blog

- Case Study

- Knowledge Center

- Encyclopedia

- Story

- Video

- Blog Type

- Product

- Topic

- Region

- Home

- Blog

- Case Study

- Knowledge Center

- Encyclopedia

- Story

- Video

- English

Hot Search

- Product Updates

- Share FS

- PoE Switch

- Networking

- Networking Devices

Maintaining Proper Polarity for Pre-terminated Fiber Cable System

For today’s data center, the increased high-density fiber links offered by the pre-terminated modular system have proven to be extremely valuable in space-constrained installations. However, when upgrading to 40/100G devices with the existing 10G devices, some data center operators could face the challenge of getting the correct fiber polarity. Read this article to learn about maintaining proper polarity in pre-terminated fiber cable systems.

Why Need Consider Fiber Polarity at Modular Patch Panel?

A typical fiber optic link requires two fibers for full duplex (two-way) communications, it is very important to ensure that the transmit signal at one end of the link is mated with the corresponding photo detector of the receiver at the other end. For the multi-fiber link, bidirectional transmission, multiple connections and splices along the link further complicate the system design. Pre-terminated fiber patch panel (including adapter panel and fiber cassette) is the heart of a modular fiber system, which supports groups of full duplex fiber connections. Therefore, it will be important to consider assuring the proper polarity of these array connections from end-to-end.

Three Polarity Management Methods for Fiber Optical System

The TIA/EIA has developed a standard that addresses the polarity issues associated with multi-fiber array connections. There are three methods (Methods A, B & C) for point-to-point fiber links using array connections to assure the correct polarity. Once one of particular connectivity method is selected, a set of the common fiber cables, array cables, and transmission components should be used throughout the installation. The following will discuss the three polarity management methods of MTP®-12 trunk cable:

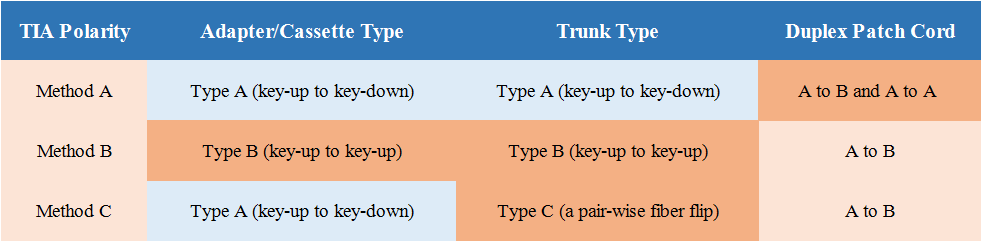

Table 1: Three Polarity Management Methods.

(1) TIA Polarity: Method A

Method A achieves fiber polarity by using A to A patch cord, in which the transmit-receiver flip must happen. The trunk cable is a straight through transmission, with the key-up on one end, and the key-down on the opposite end. All components in the channel are mated key-up to key-down.

(2) TIA Polarity: Method B

Method B achieves polarity by dictating all components in the system are mated key-up to key-up. The straight through patch cord (A to B patch cord) is used at both ends. The fiber of trunk cable is mated position 1 with position 12.

(3) TIA Polarity: Method C

Method C uses a pair-wise fiber reverse in the trunk cable to correct for polarity. Each adjacent pair of fibers at one end are flipped at the other end, which means position 1 is mated with position 2, position 3 is mated with position 4, etc. This enables the use of the same module type on both ends of the channel and standard patch cords.

For more information about fiber polarity, please refer to Understanding Polarity in MTP® System.

Polarity Management for Modular Fiber Cassette

Modular fiber cassettes are enclosed units that contain 12 or 24-fiber factory terminated fan-outs inside. These cassettes provide a transition from MTP® connector at the rear to SC, LC, ST-style or MT-RJ connectors at the front of the cassettes. The fan-outs are completed in the internal fibers for converting and routing the connections.

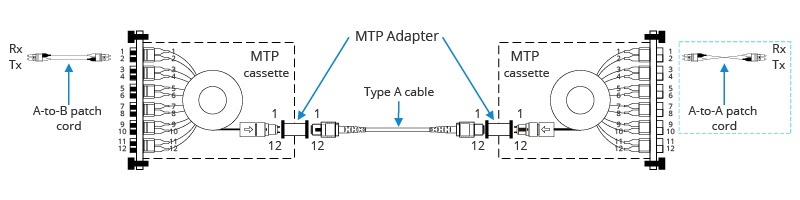

(1) Method A: Polarity Reverse in A-to-A Patch Cord

This method requires A-to-A patch cable on one end of the system for polarity flip. The Type A MTP®/MPO cassette makes a “key-up to key-down” connection between the internal MTP® connector and the MTP® array cable connector. Method A system can work for both single-mode and multimode channels. By the way, with FS.com fiber optic cassette configuration, Type A and AF cassettes are used as a pair in a Method A link, you no longer need to use A-to-A patch cable. It provides an easy way for proper interconnection.

Figure 1: Connectivity Method A.

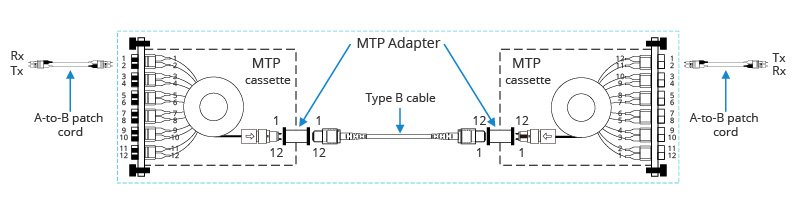

(2) Method B: Polarity Reverse in Fiber Cassette

This method requires one of the cassette pairs to have reversed polarity, which employs key-up to key-up straight-through link. The fiber channel is completed by utilizing A-to-B patch cables at both ends of the link. But the Method B is not available for single mode networks.

Figure 2: Connectivity Method B.

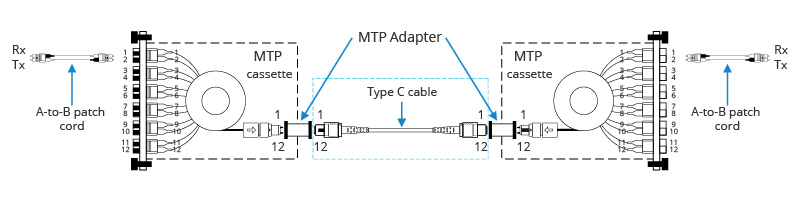

(3) Method C: Polarity Reverse in the Trunk Cable

This method is only available when using a micro distribution trunk cable, because the polarity reverse is achieved within the trunk cable itself through pair-wise flipping of individual fiber pairs. The fiber channel is also completed by utilizing A-to-B patch cables at both ends of the link.

Figure 3: Connectivity Method C.

Polarity Management for Fiber Patch Panel

Fiber patch panel is often used in fiber optical cabling. In the process of connecting, the fiber cable is terminated with SC or LC adapters on the fiber patch panel. Some people may be confused about whether need to flip fiber pair at the connector. If so, should this cross-connection be made in one of the end or both ends to get correct polarity? Here will give you answer.

Figure 4:Polarity Management for Fiber Patch Panel.

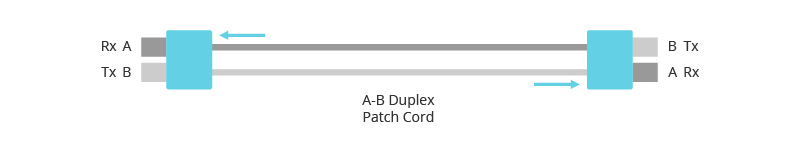

Maintaining proper polarity in fiber optic cabling involves ensuring that the "B" transmit signal connects to the "A" receive signal. Polarity reversal is often required when connecting optical fiber from a patch panel to another device. There are two types of serial duplex pair connections available: "A-to-B" patch cords for "straight-through" wiring and "A-to-A" patch cords for "crossover" wiring.

The recommended practice is to perform the polarity reversal at the patch panel. This allows for better tracking of cable switching within the fiber patch panel. In traditional standard patch cords, the polarity reversal can only be achieved on one of the patch cables, similar to Method A mentioned earlier.

On the other hand, LC uniboot patch cords have been developed for easy polarity reversal without the need for re-terminating the connectors. There are two basic design principles for achieving polarity reversal with LC uniboot patch cords. One method involves switching the A and B positions of the patch cord, while the other method involves rotating the connector 180 degrees to exchange their positions.

Conclusion

Modular fiber patch panel cabling technology offers many advantages facilitating high performance, rapid and error-free installation and reliable robust operation. The best way to maintain correct optical polarity in these systems is to select a standards-based approach and to adhere to it throughout an installation. For more information, please feel free to visit FS.com.

Related Resource:

You might be interested in

Email Address

-

PoE vs PoE+ vs PoE++ Switch: How to Choose?

Mar 16, 2023