How Much Do You Know About PLC Splitter?

What Is PLC Splitter?

PLC splitter, also called Planar Waveguide Circuit splitter, is a device used to divide one or two light beams into multiple light beams uniformly or combine multiple light beams to one or two light beams. It is a passive optical device with many input and output terminals, especially applicable to PON (EPON, GPON, BPON, FTTX, etc.) to connect the MDF (main distribution frame) and the terminal equipment and to branch the optical signal.

PLC splitter provides a low-cost light distribution solution with high stability and reliability. PLC splitters can offer a splitting ratio of up to 1x64, which is generally higher than the splits of FBT splitter that another common type of optical splitter. To learn more about these two types of optical splitter: FBT Splitter vs. PLC Splitter: What's the Difference?

PLC Splitter Manufacturing Technology

PLC splitter is based on Semiconductor technology. As its name shows, PLC splitters are manufactured by planar waveguide circuit technology. PLC splitter design consists of one optical PLC chip and several optical arrays depending on the output ratio. The optical arrays are coupled on both ends of the PLC splitter chip.

Figure 1: PLC Splitter Design

PLC chip is one key component of a fiber PLC splitter. It is available in 1xN (N=2, 4, 8, 16, 32, 64) and 2xN (N=2, 4, 8, 16, 32, 64) splitting ratios. The figure below shows the typical design of a 1x8 PLC splitter chip.

Figure 2: Design of A 1x8 PLC Splitter Chip

Classifications of PLC Splitters

PLC Fiber Optic Splitter can be categorized by the PLC splitter chip they use, meaning there are 1xN and 2xN PLC splitters, such as 1x4 splitter, 1x8 splitter, 1x16 splitter, 2x32 splitter, 2x64 PLC splitters, etc. Users can choose different input and output numbers depending on subscriber conditions or cable length. In addition, PLC splitters also can be classified based on different packages to meet clients’ needs in various scenarios, including small size PLC splitter that needs to be used in terminal boxes and big size rack mounted PLC splitter that can be installed in racks. There are five types of PLC splitters in the market: Bare Fiber Optical Splitter, Blockless Fiber Splitter, ABS Splitter, LGX Splitter, and Rack-Mount Splitter. For more information: How Many Fiber Optic Splitter Types Are There?

How Does PLC Splitter Work in PON Network?

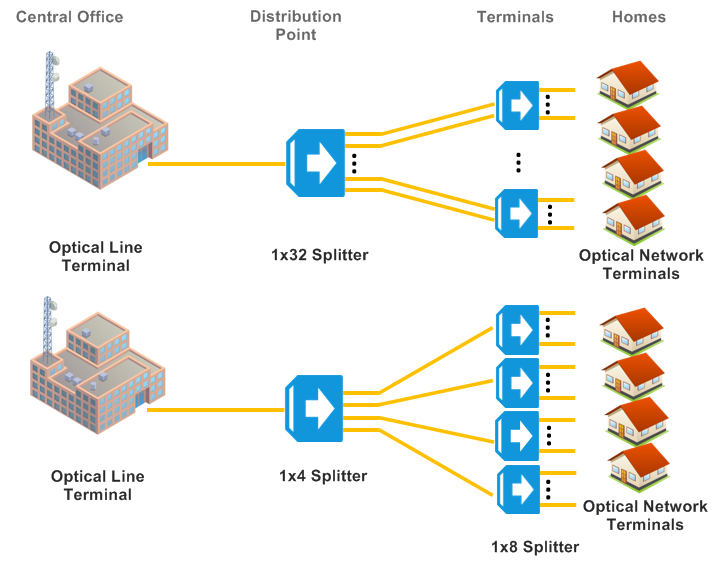

In passive optical networks (PON), a PLC splitter is widely installed between the PON Optical Line Terminal (OLT) and the Optical Network Terminals/Units (ONTs/ONUs) that the OLT serves. The single fiber link coming from the Central Office (CO) OLT is connected with the input of a splitter and is split into a given number of fibers leaving the splitter. The number of outputs in the PLC module determines the number of splits.

PLC splitters can be used in centralized PON architecture or distributed architecture. In a centralized PON architecture, a 1x32 PLC splitter is often used in the Central Office. In a distributed PON architecture, a 1x4 PLC splitter is firstly directly connected to an OLT port in the Central Office, then each of the four fibers is routed to an outside plant terminal/enclosure box that houses a 1x8/1x4 PLC splitter. For more detailed information, please visit Fiber Splitter: Centralized Splitting vs Distributed Splitting.

Figure 3: Applications of PLC Splitters

Conclusion

As demand for higher bandwidth continues to grow, telecommunications companies rely on the PON network and need reliable PLC splitters to provide fiber optic links to an increasing number of users. PLC splitters allow a single PON network interface to be utilized by multiple users, maximizing a fiber network’s user capacity, offering the best solution for network builders.

You might be interested in

Email Address

-

PoE vs PoE+ vs PoE++ Switch: How to Choose?

Mar 16, 2023