- English

- German

- French

- Spanish

- Japanese

- Italian

- Chinese

- Chinese (traditional)

- Home

- Blog

- Case Study

- Knowledge Center

- Glossary

- Story

- Video

- Blog Type

- Product

- Topic

- Region

Hot Search

- Product Updates

- Share FS

- PoE Switch

- Networking

- Networking Devices

- Home

- Blog

- Case Study

- Knowledge Center

- Glossary

- Story

- Video

-

- Home

- Blog

- Case Study

- Knowledge Center

- Glossary

- Story

- Video

- Blog Type

- Product

- Topic

- Region

- Home

- Blog

- Case Study

- Knowledge Center

- Glossary

- Story

- Video

- English

Hot Search

- Product Updates

- Share FS

- PoE Switch

- Networking

- Networking Devices

Pre-terminated Cabling System for Data Center Structured Cabling

Field termination has been widely used during the deployment of data center in the past years. However, with the data center increasingly dependent on high-density cabling, traditional field termination methods will result in extended deployment time, higher installation costs and increased downtime. To solve these issues, a pre-terminated cabling system, which can accelerate the installation process, reduce costs and errors, is introduced to the data center cabling system.

What’s Data Center Structured Cabling?

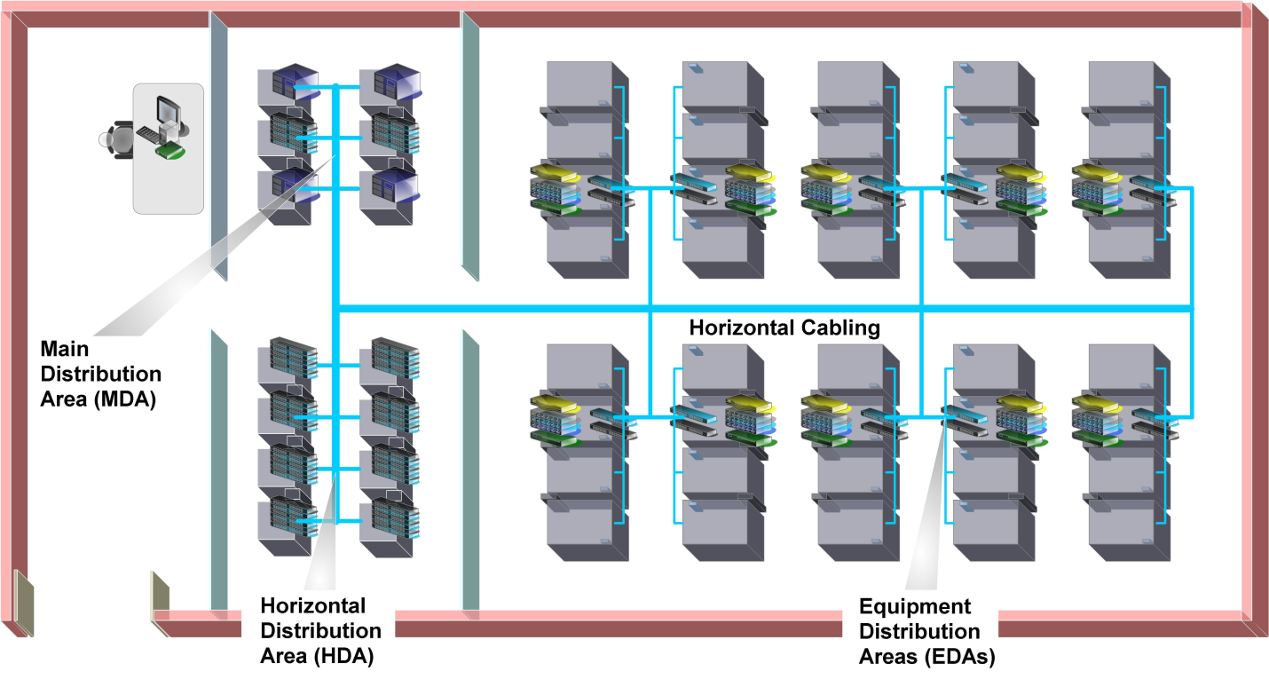

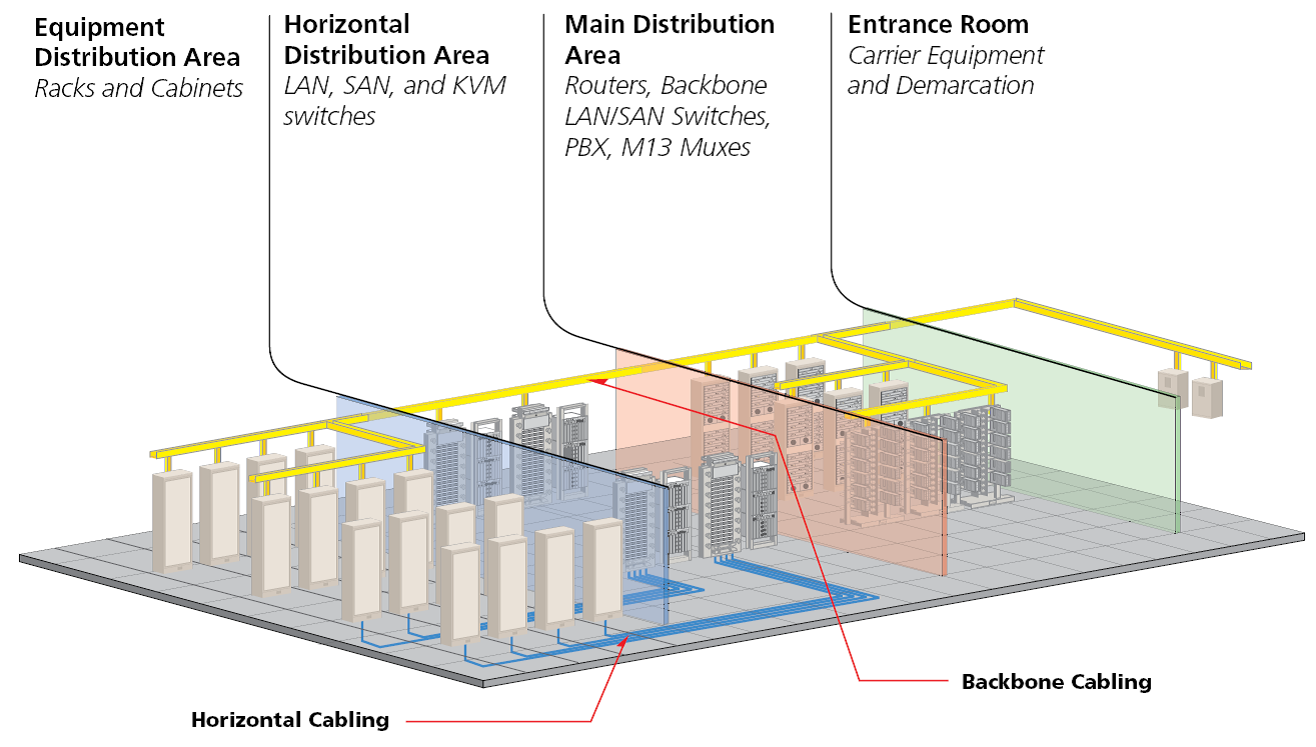

Data center structured cabling is a telecommunications cabling infrastructure consists of a number of standardized smaller elements. According to TIA-942 standard, a data center cabling system always includes five key functional subsystems: Entrance Room (ER), Main Distribution Area (MDA), Horizontal Distribution Area (HDA). Zone Distribution Area (ZDA), and Equipment Distribution Area (EDA). MDA data center holds the main cross-connect, the core routers and LAN/WAN switches. HDA acts as the telecom room. ZDA is the consolidation point for all the data center network cabling and switches. EDA is the main server area where the racks and cabinets are located.

Image source: EEP (Electrical Engineering Portal)

Generally, there are two types of cabling design for connecting the above mentioned systems: backbone cabling and horizontal cabling. Horizontal cabling supports mechanical termination, patch cord and horizontal cross-connect to the HDA, which may connect either to the ZDA or the EDA. Horizontal cabling can be fiber, copper or a mix of both. Backbone cabling on the other hand simplifies the design of the data center network cabling as it supports patch cord, mechanical termination and main cross-connects to various areas of the data center. Read more details on backbone cabling and horizontal cabling at Backbone Cabling vs Horizontal Cabling

Pre-terminated Fiber/Copper Cabling Location in Data Center Structured Cabling

Pre-terminated fiber/copper cabling solutions are ideally suited for data center cabling design in MDA, HDA and ZDA areas. Usually, pre-terminated fiber-optic cable assemblies offer high-density small-form-factor cabling-up to 144 fibers per cable and are used as backbone MDA network cabling. Pre-terminated copper assemblies are typically comprised of bundles of 6 or 12. They are used in the HDA to connect switch cabinets to server cabinets, and in the ZDA to run from the HDA to zone boxes. The following figure shows the data center wiring diagram.

Image source: Cansol Consulting

Common Pre-terminated Cables for Data Center Structured Cabling Installation

Pre-terminated cable provides a plug-and-play solution for links between switches, and servers in the data center. These solutions often include MTP® fiber cables, fiber patch cables, and Pre-terminated copper trunk cables.

MTP®/MPO Pre-terminated Cable

Pre-terminated with high-quality and good-performance MTP®/MPO connectors, this pre-terminated cable can meet the demand for high speed and high density in the current and future network. Generally, there are MTP®/MPO trunk cables and MTP®/MPO harness cables, MTP®/MPO PRO trunk cables and MTP®/MPO conversion cables in this category. At the same time, these MTP®/MPO cables also provide OS2/OM3/OM4 and OM5 types. Both these pre-terminated cables can be used for 100G, or even 400G applications.

LC/SC Pre-terminated Fiber Patch Cable

Fiber patch cables can be divided by connector types, fiber counts, and core diameter. Connector types include LC, FC, SC, ST, and more. Fiber count can be classified as simplex (single fiber) or duplex (two fibers). Core diameter distinguishes between single-mode and multi-mode fibers. Fiber patch cable helps to ensure a reliable temporary fiber optic interconnection, making it become the most commonly used pre-terminated fiber cable in data center.

Pre-terminated Copper Cable

Pre-terminated copper trunk cables provide a quick plug-and-play solution for links between switches, servers, patch panels, and ZDA in the data center. With the right upfront planning and coordination, these trunks can offer major benefits over terminating twisted-pair cable in the field. Copper trunks are typically comprised of bundles of 6, 12, or 24 and factory terminated with jacks and plugs. There are various pre-terminated copper trunk cables available in Cat5e, Cat6 and Cat6a UTP and STP cable construction with different termination types, such as jack to jack, jack to plug, plug to plug, etc. on the market.

When to Use Field Terminated vs. Pre-Terminated Fiber Optic Cables

Field terminated fiber optic cables are suited for situations that require customization and future modifications. Pre-terminated fiber optic cables are perfect for projects that demand quick deployment and plug-and-play convenience. Common pre-terminated cables including MTP® fiber cables, fiber patch cables, and copper trunk cables are good choice for efficient connection in your data center.

Conclusion

Pre-terminated cabling solutions are designed for rapid deployment in data center structured cabling installation and upgrade. They are ideal for environments where performance, flexibility, and scalability are critical. As the on-line leader in providing data center solutions, FS.com offers all kinds of Pre-terminated MTP®/MPO cables, LC/SC Pre-terminated cables and Pre-terminated copper trunk cables. All of our products are 100% tested for good quality and high performance. Custom services are also available for special needs.

You might be interested in

Email Address

-

PoE vs PoE+ vs PoE++ Switch: How to Choose?

May 30, 2024